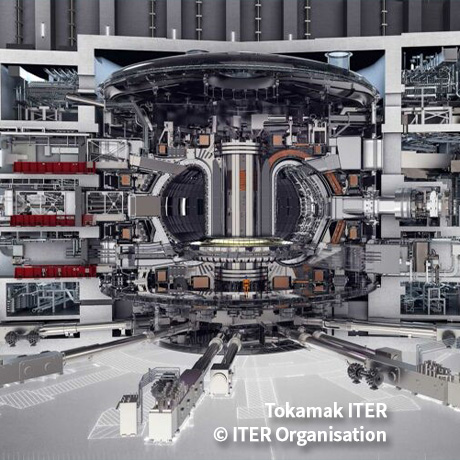

Preliminary Design of the Biological Shielding for the Tokamak Top Lid at ITER

P. Martínez-Albertosa, P. Sauvana, J. Bergmanb, M. Loughlinb, Y. Le Tonquezeb, M. Thompsonb, R. Juáreza

Fusion Engineering and Design 195 (2023)

During the operational phase of the ITER project (International Thermonuclear Experimental Reactor, also meaning “The Way” in Latin), electronic equipment located in the hall above the tokamak will be exposed to neutron and photon fields from both the plasma and the activated water.

To protect the electronics, the implementation of dedicated shielding on the crane hall platform and the bioshield top lid is required.

The design demands optimisation in terms of structural engineering, weight limits, and radiation shielding requirements. This study analyses eight shielding configurations, assessing neutron flux and accumulated dose over 4,700 hours of operation at 500 MW power. These conditions correspond to a neutron wall load of 0.3 MW/m², in line with ITER project specifications.

An innovative approach, based on intermediate sources, has been adopted. This method integrates all relevant radiation sources while optimising calculation times. The results of these analyses were presented during the review of the conceptual study in order to support the decision-making process, particularly with regard to the biological protection of the Top Lid.

The study demonstrates that using Mortar 075 significantly reduces the dose rate, ensuring the required shielding for critical electronics above the tokamak.

METHOD:

The latest Tokamak Complex MCNP model was used for all cases, modified to include the different shielding configurations studied. The primary objective was to identify the optimal configuration in terms of material selection, thickness, and, most importantly, weight per unit area to ensure effective radiation shielding of the Top Lid.

A wide range of innovative materials was developed and analysed, including the brand-new MORTAR 075 borated mortar from the Novashield® HE (High Efficiency) range developed by Lemer Pax.

RESULTS:

For all configurations considered, approximately 95% of the dose results are due to photon contribution, mainly from the ¹⁶N decay in the water circuits. The neutron flux is dominated by plasma neutrons, and the contribution of ¹⁷N decay neutrons is negligible.

All configurations studied are compliant with the limits for critical electronics above the L4 platforms, both on the north and south tallies where electronics will be deployed. Finer resolution 3D radiation maps support this conclusion for all cases.

A The comparison of results from Cases 1 and 2 shows that the Lemer Pax MORTAR 075 offers better protection compared to standard borated mortar as neutron shielding. On average, a 70% improvement in flux reduction is observed in all measurement points.

KEY CONCLUSIONS:

All cases considered are compatible with the ITER limit for critical electronics in both the north and south platforms. However, further optimisation of the lid shielding design will be needed to balance the effect of both neutrons and photons on the radiation environment in the crane hall.

- The radiation environment in the crane hall during operation includes both neutron and photon fields from the plasma and activated water.

- Lemer Pax MORTAR 075 borated mortar is superior to standard boron mortar as a neutron shielding material.

- The design with MORTAR 075 shielding (Lid-C) has the highest neutron shielding efficiency. However, it presents the lowest photon shielding efficiency due to the removal of borated concrete.

- The MORTAR 075 wall around the bioshield has a relevant impact on results around its target area.

Click here for the digital version of the publication

a. Dept. Ingeniería Energética, Universidad Nacional de Educacion a Distancia (UNED), C/ Juan del Rosal 12, Madrid 28040, Spain

b. ITER Organization, Route de Vinon-sur-Verdon, CS 90 046, 13067 St. Paul Lez Durance Cedex, France